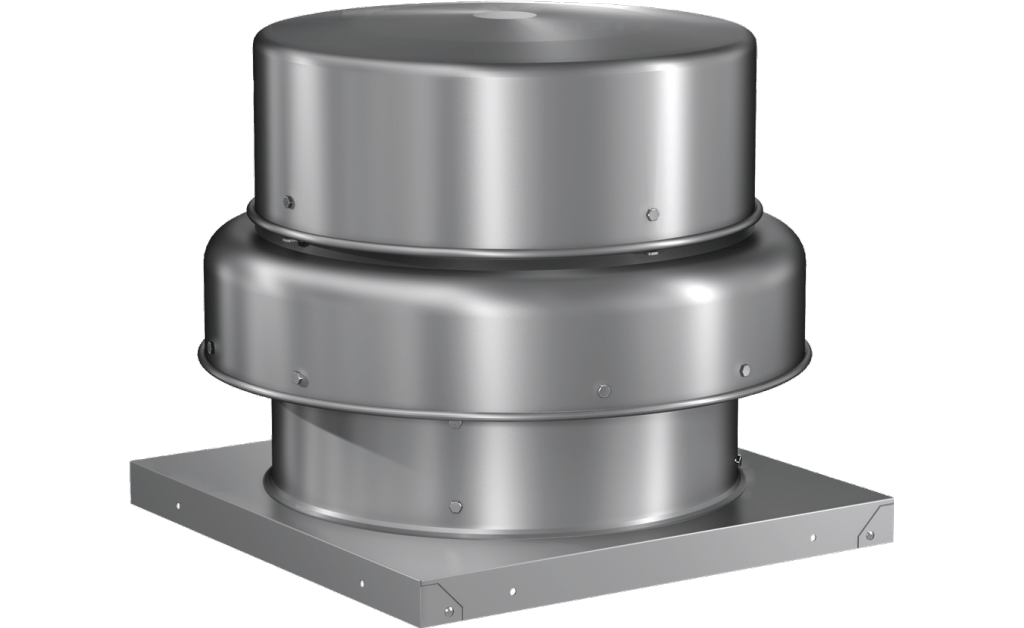

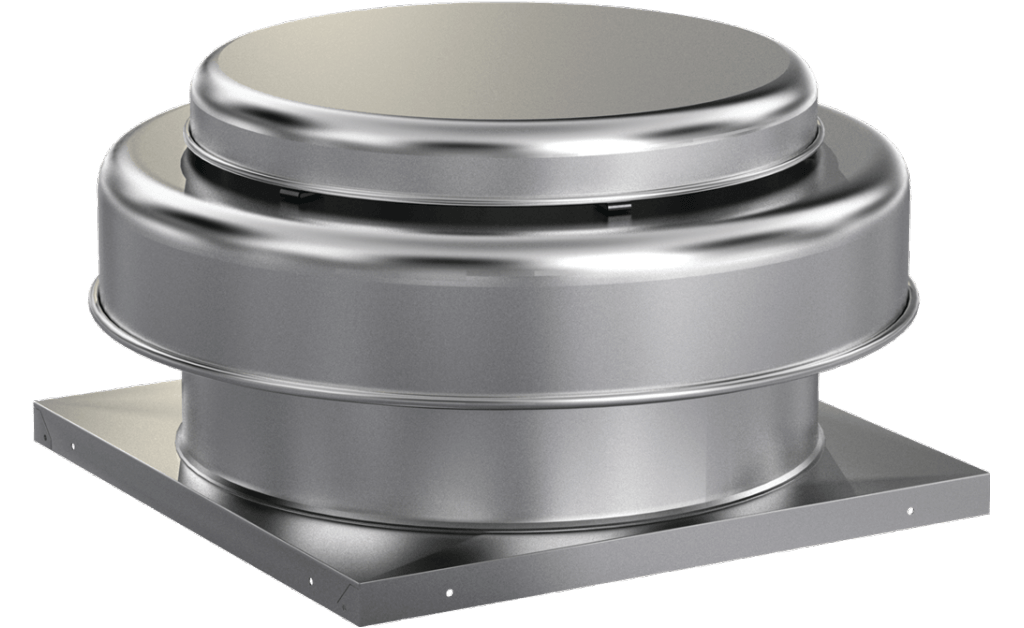

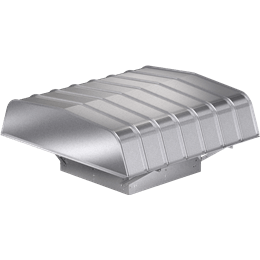

Roof curbs extensionspage header and equipment supports prefabricated roof curbs reduce installation time and costs by ensuring compatibility between the fan curb and roof opening.

Greenheck roof curb installation.

Secure ventilator to roof curb using a minimum of.

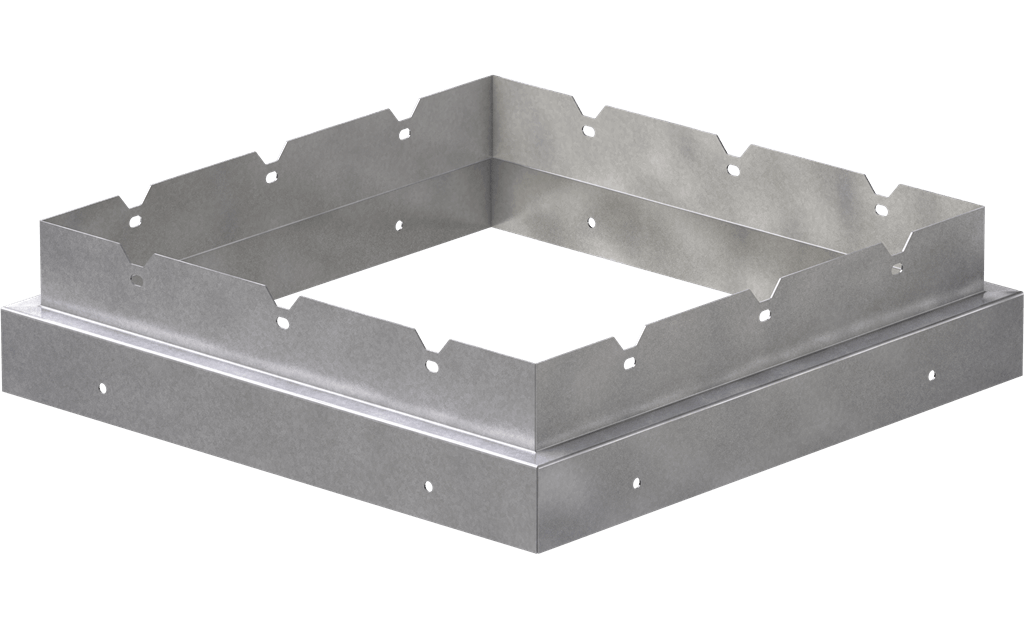

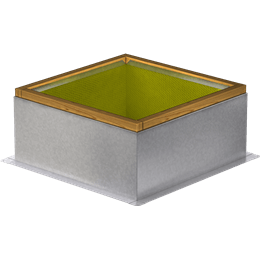

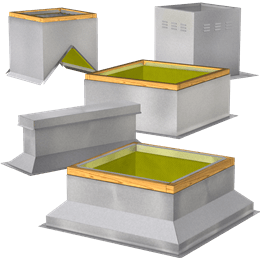

All curbs are constructed of reinforced corrosion resistant heavy.

Place latch catch on the inside of the fan curb cap and align top most hole of the latch catch with the pre punched hole on the curb cap.

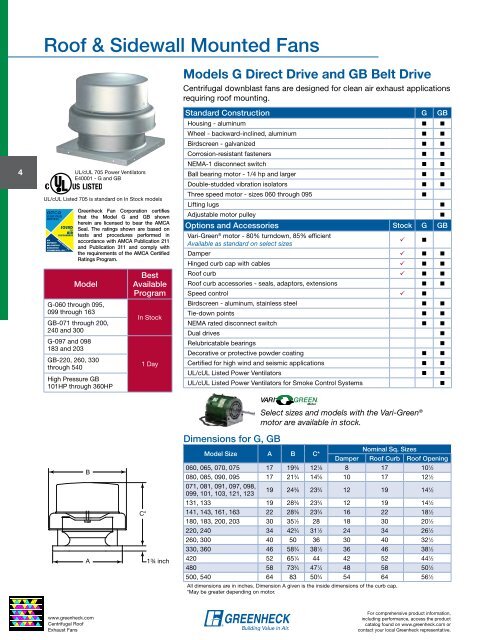

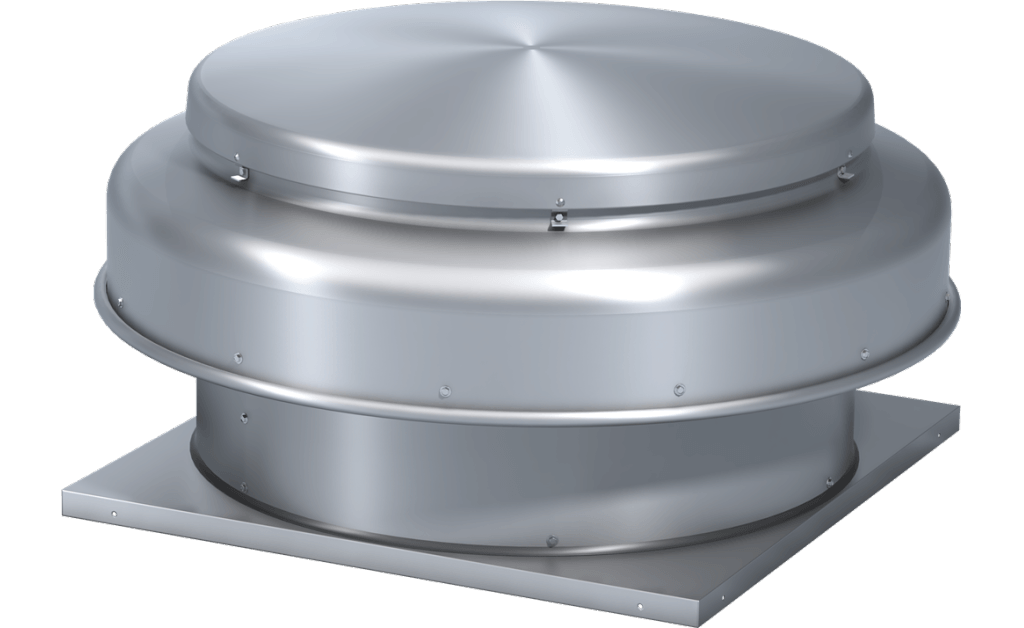

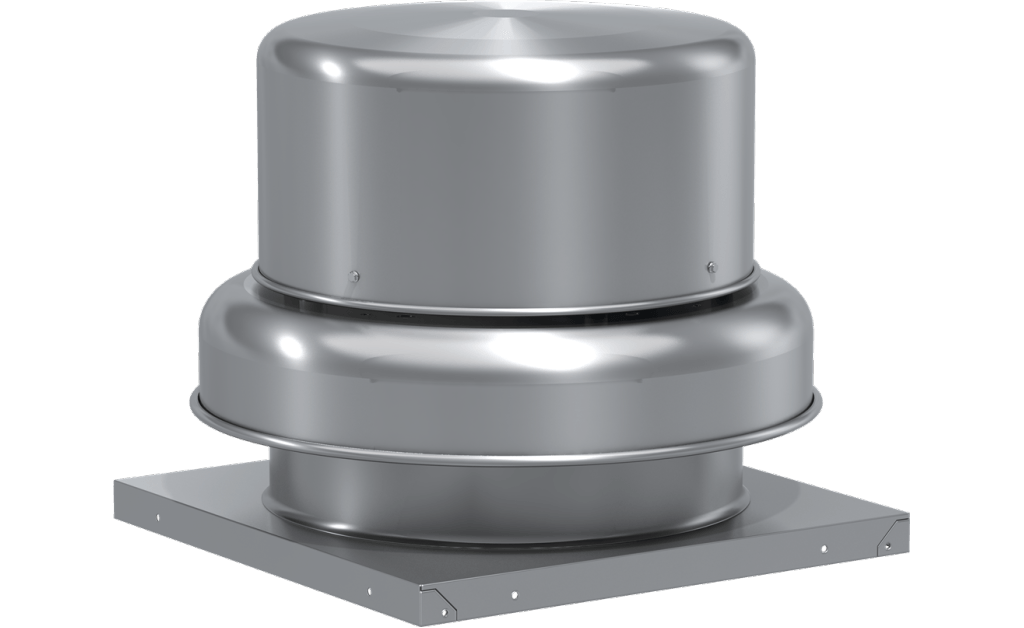

Place ventilator on curb.

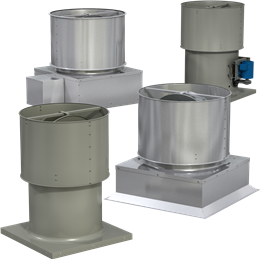

A wide variety of roof curbs are available including.

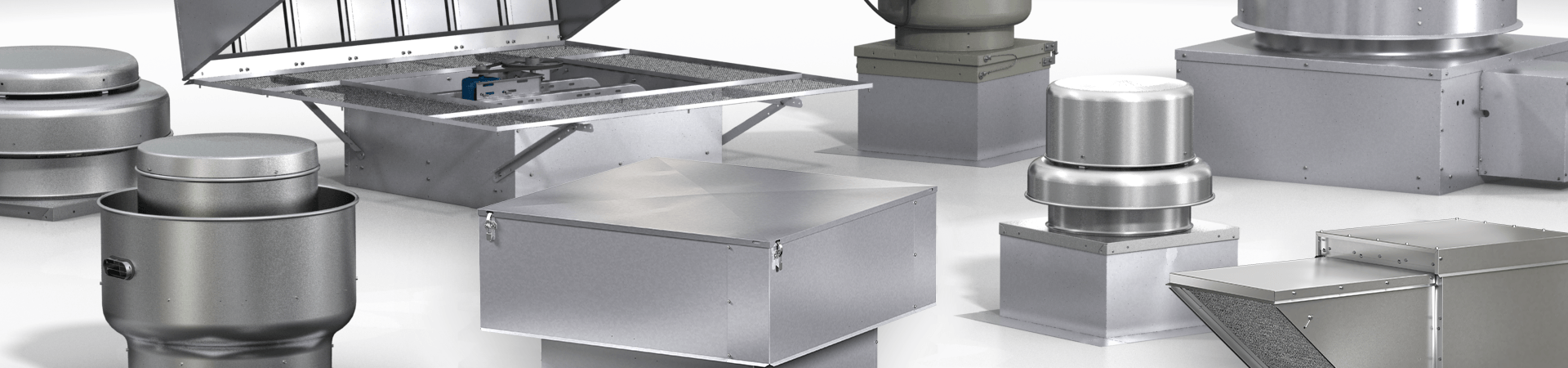

Roof curb installation dimensional data 2.

Secure damper flange to curb damper tray.

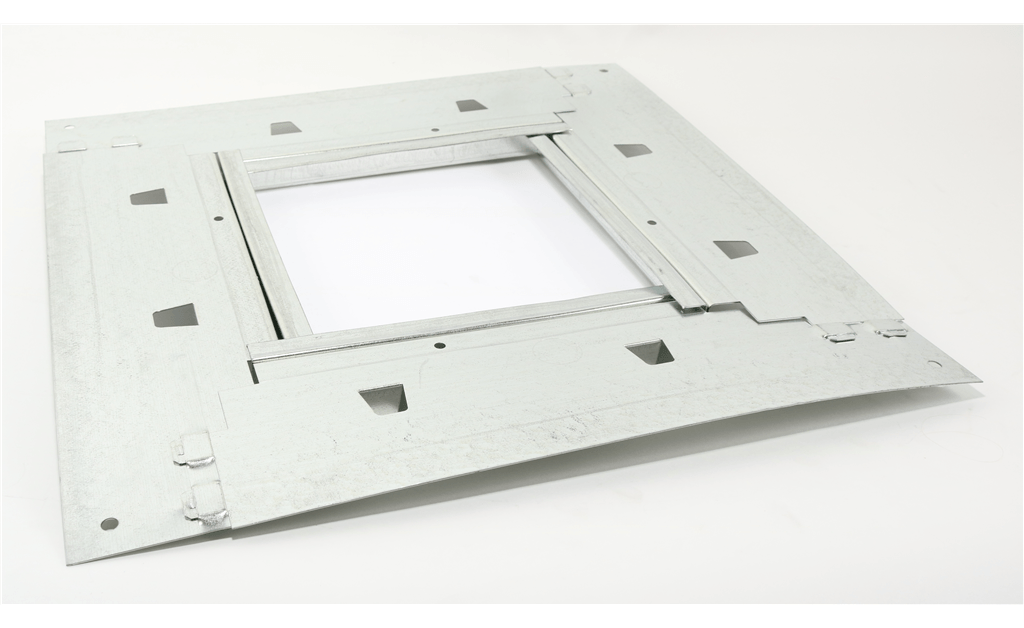

Curb cap is the inside dimension of the curb cap the roof curb should be 1 in.

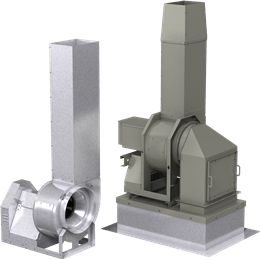

Greenheck s roof curbs are designed to meet the structural and design requirements of vektor laboratory exhaust systems.

Insert 5 16 inch 18 x 75 weld stud through the latch catch and fan curb cap hole.

Roof wall opening is a square dimension.

Weight 099 101 101hp.

On the roof surface cut an appropriate sized hole and follow manufacturer s instructions on curb installation.

Cut an appropriate sized hole in the roof surface.

Installation roof mount with a curb 1.

Shop greenheck roof curbs prefabricated roof curbs reduce installation time and costs by ensuring compatibility between the fan curb and roof opening.

38 mm less than the curb cap to allow for roofing and flashing.

Belt drive model size curb cap shaft bearings damper roof wall opening wall opening with a curb through wall approx.

Caulk and flash the curb to ensure a water tight seal.

Caulk and flash curb to ensure a watertight seal.

Curbs are available for mounting vektor exhaust fans as well as single or multiple bypass air plenum systems.

Follow curb manufacturer s installation instructions.

Installed on greenheck curbs.

The roof curb should be 1 in.

Flanged straight sided canted pitched ridged vented and sound absorbing.